Archives

Marker lights play a significant role in road safety. They are especially important for commercial vehicles, trailers, and delivery vans. Their main purpose is to clearly outline the size and presence of a vehicle, particularly in low-visibility conditions. What are position lights used for? What is their practical and legal importance? What are the differences between traditional bulbs and LEDs, and how do you choose the right solution?

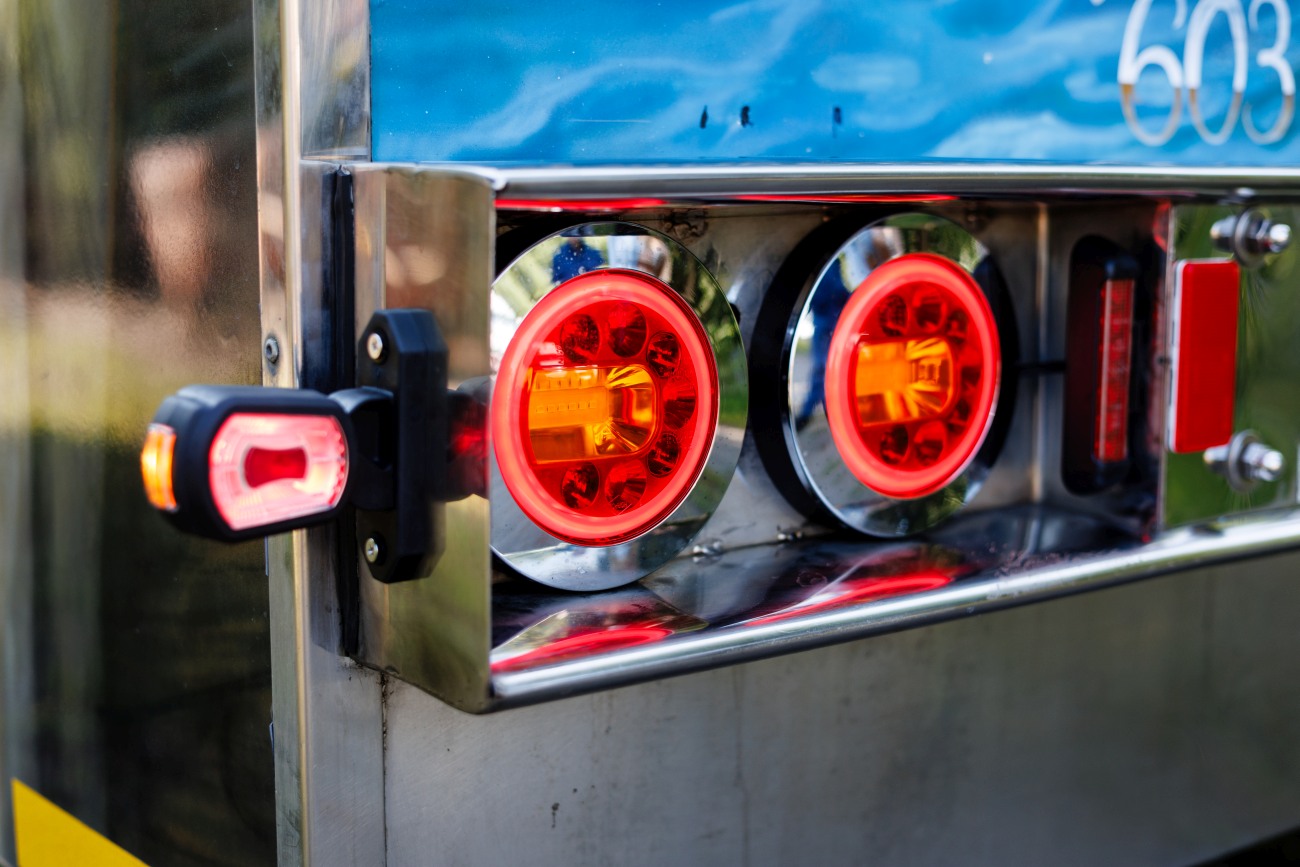

In simple terms, marker lights (sometimes called “outline lights”) are signal lamps mounted on the edges of a vehicle’s body. They may be placed at the front, rear, or sides. Their primary function is to visibly mark the vehicle’s contours for other road users. It is worth remembering that their role goes beyond aesthetics – they improve the visibility of the vehicle’s length and width, which is crucial in conditions of limited lighting, for example due to weather. In practice, a marker light emits a steady, recognizable light point indicating the vehicle’s presence and size.

What distinguishes position lights from marker lights? In Polish terminology, the two terms are often used interchangeably. However, there are subtle differences in their function and application. Position lights mark the position and outline of the vehicle mainly at the front and rear. When do we use position lights? Their primary purpose is to show that a vehicle is stationary or in motion; according to law, they must be visible from 300 meters. Current Polish regulations require position lights to be switched on whenever low beam headlights are on. They are also required during towing in poor visibility, and if hazard lights are not available – in the event of a breakdown or accident. What are marker lights used for? Their task is to more precisely indicate the sides and dimensions of a vehicle. They are used especially on vehicles with larger dimensions – such as trailers, semi-trailers, or delivery trucks. When properly selected, both systems work together to create a clear “light contour” of the vehicle and ensure visibility in all conditions.

The basic purpose of position lights is to signal the presence of a vehicle on the road. They are less intense than low or high beams, making them suitable for use in low-visibility conditions. When should position lights be used? Here are some situations:

- when parked on the road outside built-up areas – for example, on the roadside after dark;

- in limited visibility conditions when low beams are not required;

- as part of a vehicle’s lighting system when driving in a convoy or parked by the roadside.

Proper use of these lights greatly reduces the risk of collisions. Thanks to them, the vehicle outline becomes much more visible, helping to avoid dangerous situations.

Traditional position light systems using bulbs are relatively inexpensive and easy to replace, but they have a shorter lifespan and lower light efficiency. This is why LED solutions have been gaining popularity for some time. In recent years, LED marker lights and LED modules have become a standard. LED marker lights offer several advantages:

- longer lifespan and better resistance to vibrations;

- lower energy consumption;

- improved visibility with reduced power usage;

- greater design flexibility (e.g. point or strip illumination).

Their downsides include higher purchase cost and possible repair issues – often the whole module must be replaced instead of a single bulb. However, in many cases, the safety and durability benefits outweigh these drawbacks.

Correct placement of marker lights is essential. Front marker lights are usually white or amber and are mounted at the front corners of the vehicle. Rear marker lights are red, like brake lights, and indicate the rear outline. Side marker lights create an additional line of light points along the sides of the vehicle, marking its width and length.

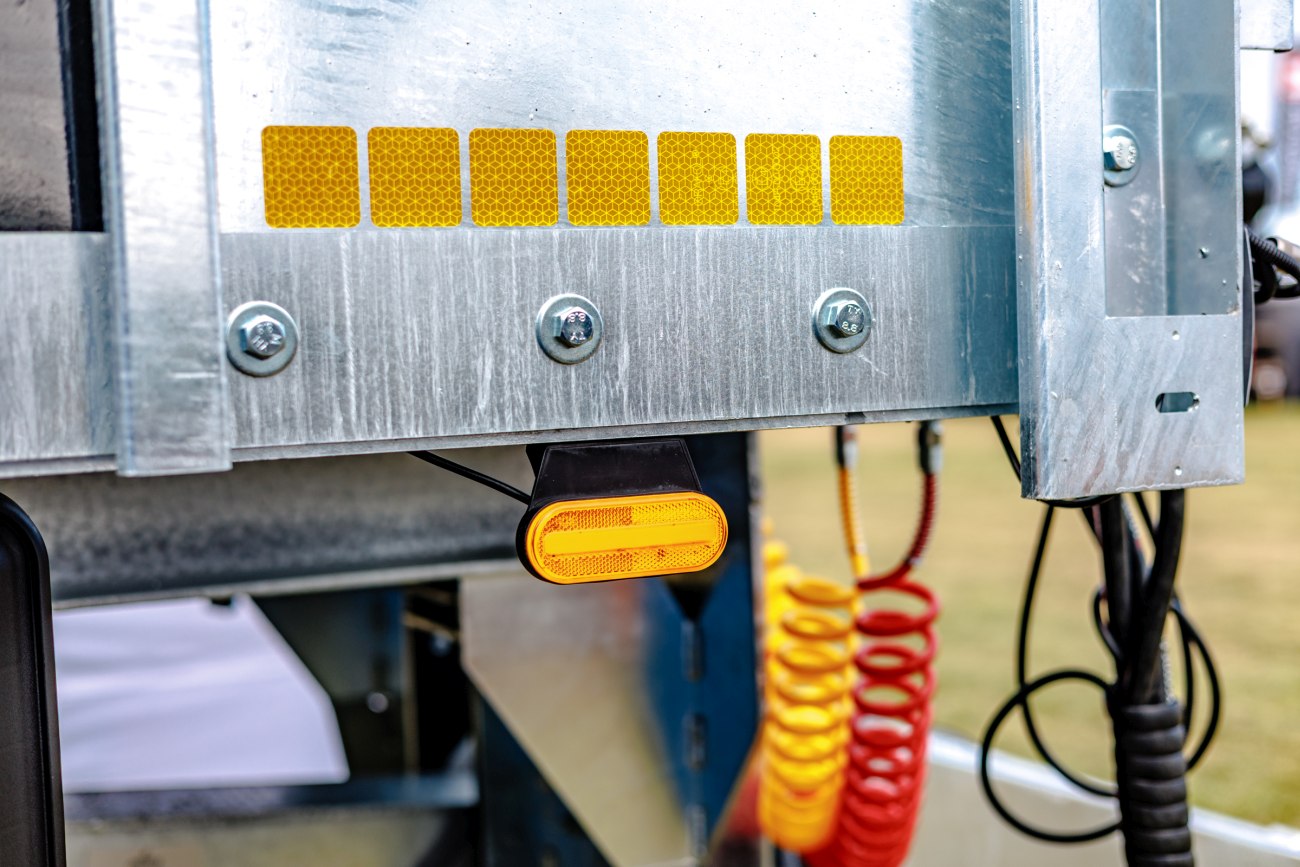

For some trailers and semi-trailers, road regulations require side marker lights – they are mandatory for vehicles and trailers wider than 2.1 m and longer than 6 m. Marker lights on passenger cars are less common because they are usually not legally required. However, they can be found on SUVs or motorhomes to improve contour visibility.

Road laws and homologation standards strictly define vehicle lighting requirements. In Poland and the EU, there are regulations specifying which vehicle categories must have marker lights, as well as their color, placement, and light parameters. The most important factor is the vehicle’s dimensions. Marker lights on a trailer are required if the total length of the vehicle and trailer exceeds 6 meters and the width exceeds 2.1 meters. Importantly, they may not be installed if the trailer is less than 1.8 m wide. Between 1.8 m and 2.1 m, their installation is optional.

Regulations also specify how and where marker lights should be installed. They must be mounted symmetrically, as far outward as possible – yet no more than 40 cm from the outermost edge. When installing LED marker lights, it is essential to follow current regulations to avoid fines and ensure homologation compliance. Regulations may differ when driving abroad, especially outside the EU, so additional preparation is required for international fleets.

We invite you to contact Horpol – we offer both individual marker lights and advanced LED modules. When choosing, consider factors such as homologation and legal compliance, as well as light parameters like brightness or beam angle. It is also important to check resistance to weather conditions (IP rating). Ease of installation and availability of spare parts also matter. For low power consumption and long service life, LED marker lamps are the best option. For older vehicles, bulb-based position lights may be sufficient.

Installing marker lights provides measurable safety benefits. These include better visibility of the vehicle’s outline – drivers approaching from the front or side can more quickly assess its size and shape. They also reduce the risk of side and rear collisions, especially during maneuvers, merging, or driving in low light conditions. Lights placed at the corners help other drivers judge how much space remains on the road. All of this leads to better visibility and therefore greater road safety, particularly when transporting large loads.

Installation and maintenance – tips

For marker lights to work effectively and serve their purpose, proper installation and regular maintenance are essential. What should you remember?

- One of the most important factors is moisture protection – electrical connections and seals should be checked regularly.

- On the road, always ensure that no cargo is blocking the lights.

- Lamp lenses should be cleaned regularly from mud, road salt, and dirt.

- Damaged or obstructed marker lights do not fulfill their function – it is better to replace them immediately than risk an accident.

When buying, choose proven products with proper homologation. Professional LED solutions offer durability, visibility, and energy efficiency in one. If you are looking for a wide range of marker lamps and modules, visit Horpol’s offer and place your order via email or phone.