Archives

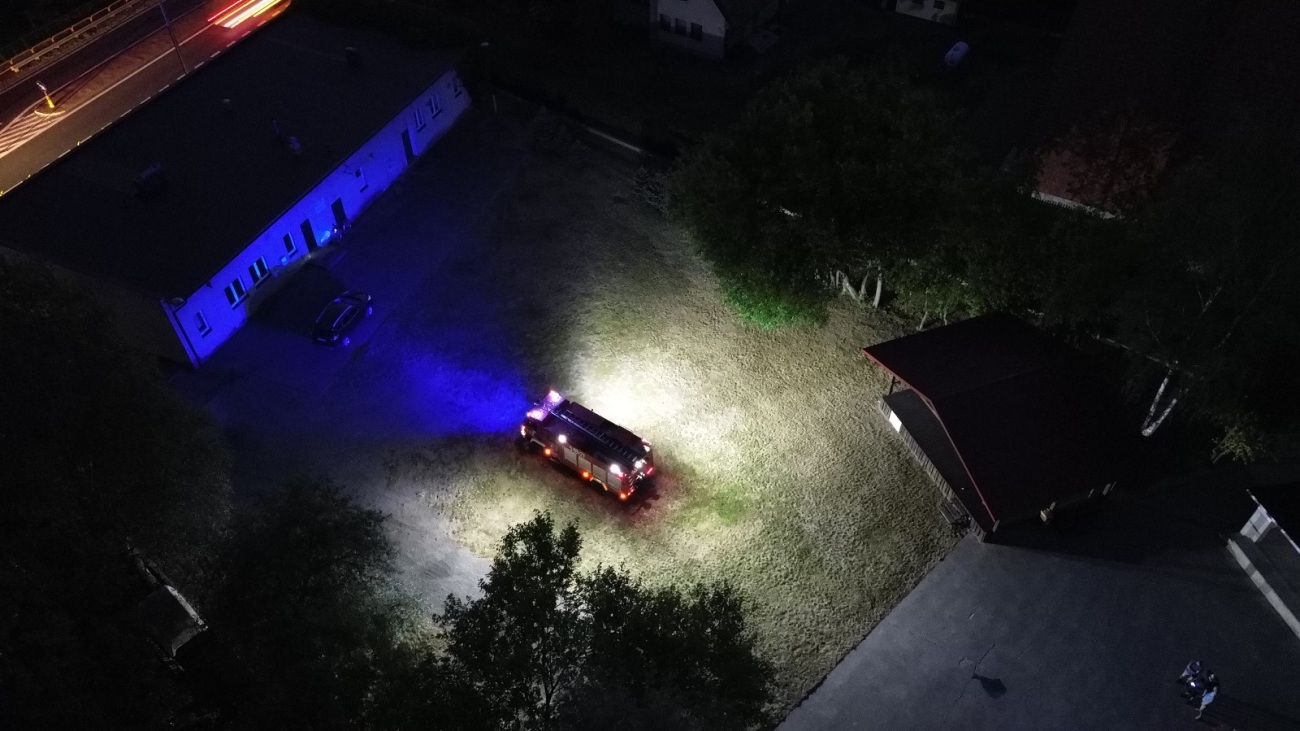

Working after dark, in difficult weather conditions, or in areas without external lighting requires proper technical preparation. One of the most important components of specialized vehicles is work lights. Their purpose is not only to improve comfort but also to ensure the safety of both the operator and people nearby.

Work lamps are specialized light sources mounted on vehicles and machinery used in industries such as construction, agriculture, forestry, transportation, and municipal services. Unlike road lights, they are not designed to illuminate roads but rather the work area – the space in which the vehicle operates or specific tasks are performed.

You’ll find work lights on excavators, loaders, tractors, sprayers, forklifts, service vehicles, and technical trailers. In each of these sectors, they enhance visibility, help avoid collisions, and enable precise maneuvering.

There is no direct legal obligation to install work lights, but they become essential when machinery operates after dark or in low-visibility conditions. According to § 37.1 of the Regulation of the Minister of Infrastructure from December 31, 2002 (Dz.U. 2003 No. 32, item 262), work lights may only be used while the vehicle is working in a construction zone – not during public road travel. This means work lights are legal and recommended, but must be used safely and according to their intended purpose.

Though the regulations do not specify one particular type of work light, these devices must meet specific standards – both in terms of light intensity and beam spread. According to ECE R23 and R10 regulations, only those lights that do not dazzle other road users and do not emit electromagnetic interference are allowed.

A 12/24V LED work light should carry appropriate approvals, and its installation must not pose a risk to traffic safety. For agricultural and construction machinery, work lights should only be used when the vehicle is stationary or operating in a closed area.

Good work lighting is a matter of convenience – but more importantly, it’s the foundation of safe operation in harsh environments. Well-chosen work lights significantly improve visibility of terrain, machines, and nearby people. This allows operators to maneuver accurately, avoid obstacles, and quickly respond to hazards, reducing the risk of collisions or accidents.

A LED work light emitting bright, focused light helps spot details during tasks – both in darkness and low visibility conditions like fog or rain. Additionally, LEDs reduce eye strain, which translates into more comfort and fewer errors. That’s why investing in modern 12/24V LED work lights is a real boost for safety and work efficiency.

Start by analyzing the vehicle’s work environment and purpose. Key factors include:

- Light range and spread – wide areas need different lighting than precision maneuvers.

- Color temperature – daylight-like tones improve visibility and reduce eye fatigue.

- Weather resistance – high IP ratings (IP 67, IP 68, IP 69), shock and corrosion resistance.

- Power supply voltage – 12/24 V LED lights are versatile and compatible with many vehicles.

- Power consumption and efficiency – LED work lights are energy-efficient and long-lasting, making them the preferred solution today.

Construction vehicles often operate in dusty, muddy, and uneven terrains. Their lights must be highly durable, shock-resistant, and capable of providing uniform, bright light in multiple directions – not just forward but also to the sides and rear. Given the harsh conditions and heavy use, LED work lights are the best choice for combining toughness with efficiency.

LED work light for excavators

Excavators require focused beam lights, typically mounted at the front and back to give operators full control of the work zone. The lights should be compact and have high ingress protection.

LED work lights for road rollers

Here, visibility around the edges of the machine is key. Diffuse LED lights mounted low, near the work surface, are ideal.

Lighting for cranes

Tall machines like cranes need long-range lights. 40–60 W LED work lights mounted on the top beam offer optimal performance.

Halogen work lights for loaders and dumpers

Older machines may still use halogen lights, but modern LED lights are superior – they resist vibration better and use less power.

Work lights with warning (strobe) functions

For machines operating around people or in low-visibility zones, LED work lights with warning strobes improve visibility from a distance and enhance overall safety.

Work lights with handle and cigarette lighter plug

For temporary lighting or frequently changing positions, portable LED work lights with handles and 12 V plugs are quick to install and don’t require electrical modifications.

Magnetic work lights

Magnetic LED work lights offer even greater flexibility, allowing for tool-free attachment to vehicle bodies or structures.

Work lamps with multifunction light

These combine work lighting with additional functions like position lights, indicators, or brake lights – ideal for vehicles that need visibility both while working and moving around job sites.

Agricultural machines often operate around the clock, in varying terrains and weather. Work lights are critical for safety and productivity, especially during harvest or fieldwork when time is crucial. Well-designed LED work lights ensure the workspace is well-lit, minimizing risks of equipment damage, operational errors, or accidents.

Tractor work lights

Should provide wide, even illumination forward and sideways. 12/24 V LED work lights are a versatile choice for modern tractors, especially for night work.

LED work light for sprayers

Sprayers need precise lighting for their booms. A narrow beam angle and white light help accurately monitor the spray pattern.

LED work lights for seeders and spreaders

These machines benefit from small, pinpoint LED work lights, allowing close monitoring of components without flashlights.

Work lights for combines

Combines require full perimeter lighting. LED lights are installed at the front, rear, and near tanks to allow visibility of both the harvesting mechanism and grain conveyors.

The choice is clear: LED technology outperforms halogens in durability, energy efficiency, and lighting quality. Halogen lights can’t match modern solutions in terms of efficiency or resilience. Additionally, LEDs instantly reach full brightness, stay cooler, and are more resistant to mechanical damage.

For most applications, LED work lights are the better choice – reliable, efficient, and long-lasting even under intensive use. They’re an investment that pays off quickly, whether for construction or agricultural equipment.

Work lights come in round, rectangular, and square forms. Selection depends on mounting space and beam angle needs. Compact LED work lights are perfect for spot lighting, while wide-beam models are typically roof- or rear-mounted for even coverage. Some models feature adjustable mounts, allowing precise light direction – ideal for dynamic work environments.

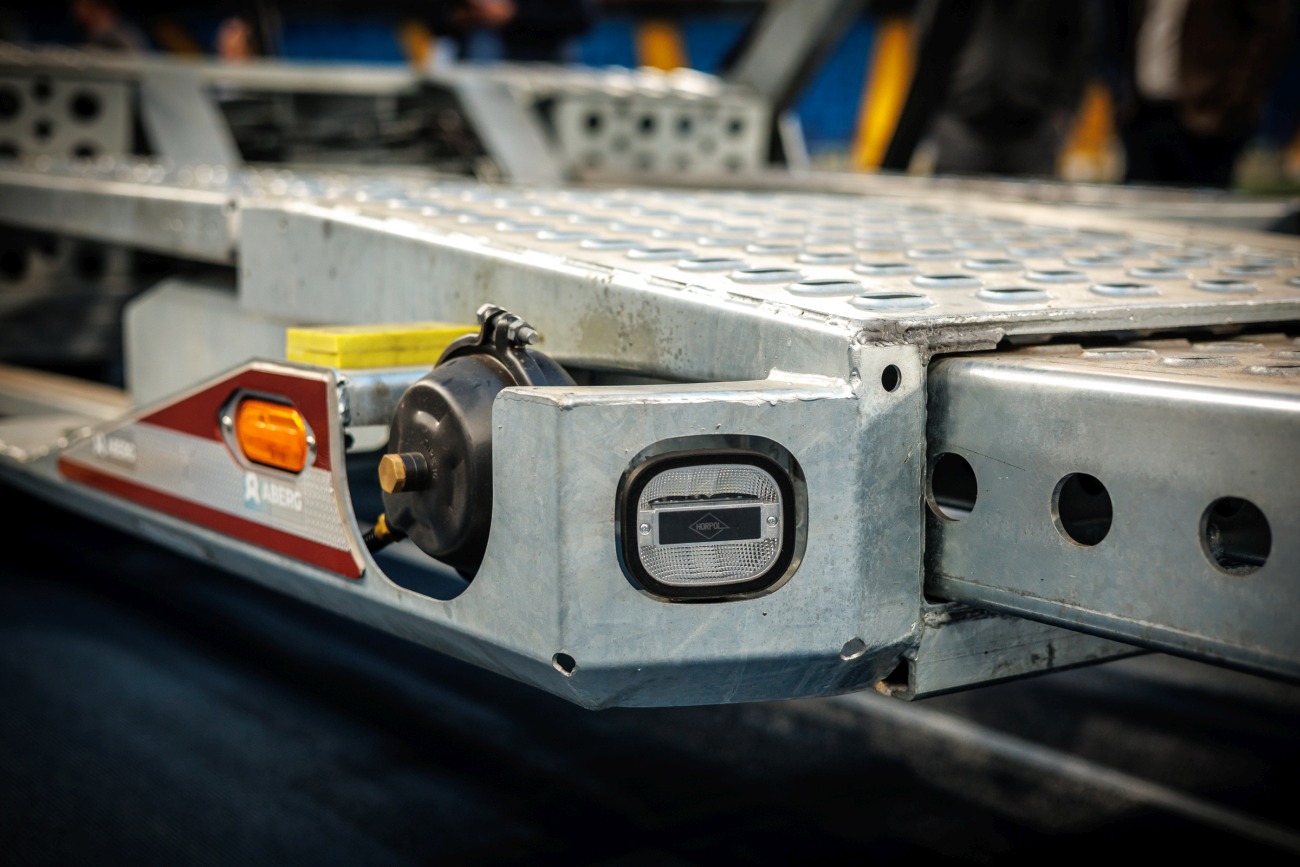

Choose reliable work lights

Lighting manufacturer Horpol offers a wide range of modern work lights for both construction and agricultural vehicles. Our selection includes durable LED lights, resistant to shocks and extreme weather. Whether you need a 12/24 V LED light for a tractor or a high-power LED work light for construction machinery, Horpol’s solutions deliver reliability in any condition.